High Speed Lamination and Flat Blank Stacking

Delivers mobility and manageability, all while maintaining the highest level of performance possible. Our professional engineering staff delivers unprecedented dedication to develop systems to satisfy the most demanding requirements.

Operational Benefits

- Achieve straight side stacks at high speeds

- Presents operators with stacks to programmed number of laminations

- Eliminates the hazards of handling lamination shoots

- Eliminates loading and unloading of laminations into the shoots at set-up

- Greatly reduces the storage requirements for tooling

- Operator can see die damaged parts within inches of stamped product (reduces scrap)

- Reduces changeover time

Common Equipment Features

- Achieve press speeds of 250 to 400 spm depending on lamination configuration and thickness

- Continuous stacking operation without stopping the press during stack exchange

- Some models capable of dual lane stacking

- Maintains part orientation throughout whole process in most cases

- All high speed linear motion is guided by profile rail bearings

- Integrated into the press controls with proper timing and sequencing of stacker operations

- Programmable final stack height from operator screen

- Presents final stacks to operator for final wiring and handling

- Designed to allow multiple part tooling set-ups with minimal tooling change

- Quick change tooling allows the customer to change from one part number to another

- Contains proper guarding and door interlocks surrounding stacking operation

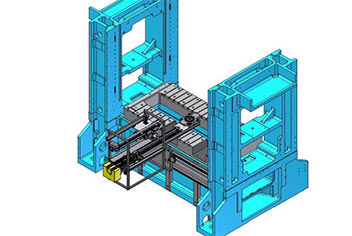

Above Bed Stacking (ABS)

The Above Bed Stacking (ABS) System receives stamped laminations above the press bed through a modified bolster and presents them to the operator on the side of the press.

Custom designed and built for each application, automatic load/unload systems increase pressroom production while at the same time creating an efficient, operator safe work place. Automatic load/unload systems is the…

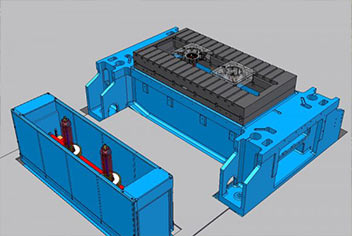

Below Bed Stacking (BBS)

The Below Bed Stacking (BBS) System receives stamped laminations through the die and bolster, extracts them below the press and presents them to the operator at floor level.

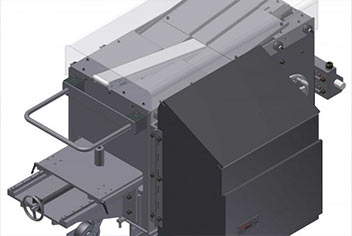

Die Ejection Stacking (DES)

The Die Ejection Stacking (DES) System is designed to catch and remove parts being ejected from the upper die.

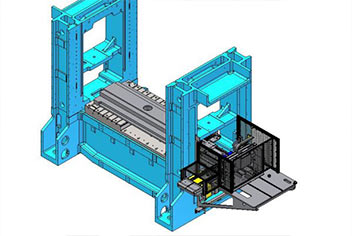

End of Crop Stacking (ECS)

The End Crop Stacking System (ECS) is an end cut operation that allows the stacker to catch the lamination as it is being cropped from the end of the die…